The new frontier of agriculture is not in the soil—it’s in the system.

What Is a Protein Bioreactor?

A protein bioreactor is essentially a controlled environment where cells grow and produce animal-free protein. Instead of raising livestock or harvesting crops, scientists cultivate specific cells that can replicate the nutritional and textural qualities of meat, milk, or eggs—entirely within stainless-steel tanks.

These reactors are designed to mimic the conditions of animal tissue: temperature, oxygen, and nutrient balance. The result is real protein, produced at scale, without the environmental and ethical costs of traditional farming.

The Shift: From Livestock to Logic

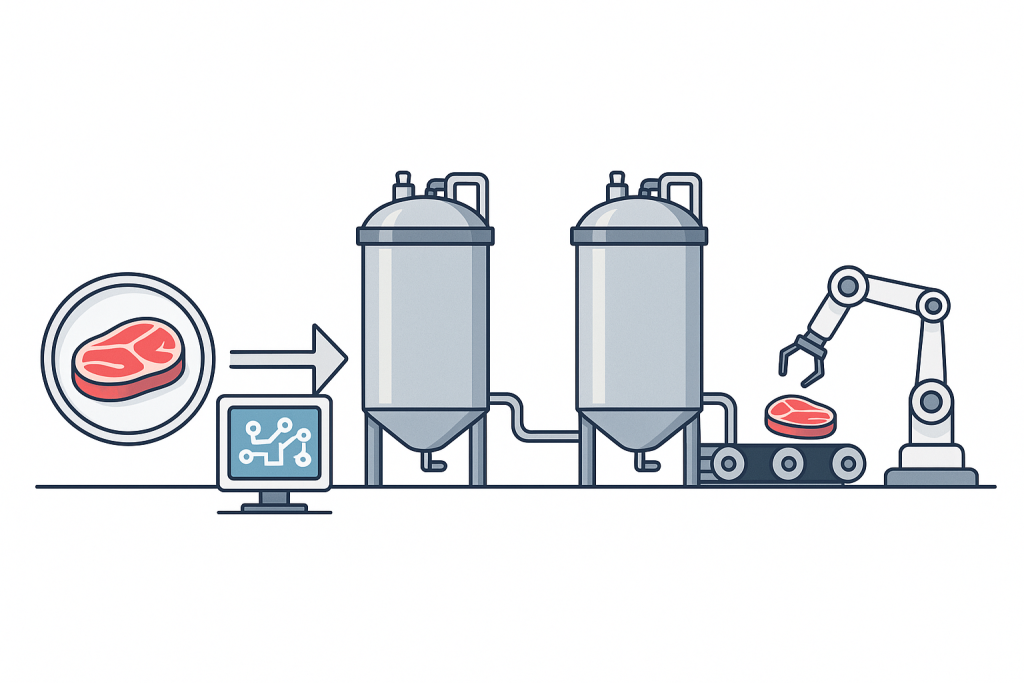

Cellular agriculture replaces biology’s slow cycles with automated precision. A modern protein bioreactor functions like an intelligent manufacturing line: sensors track pH, oxygen, and nutrient flow; algorithms adjust conditions in real time; and robotic systems manage harvesting and filtration.

Automation allows consistency—batch after batch—without the unpredictability of disease, weather, or feed shortages. The production process resembles high-tech brewing more than animal husbandry, transforming the idea of what a “farm” can be.

System Architecture: How It Works

A typical automated protein bioreactor system includes several core layers:

- Input Layer: Nutrient feedstocks—amino acids, vitamins, sugars—are prepared in sterile tanks.

- Growth Chamber: Cells multiply within a temperature- and pressure-controlled vessel, supported by a scaffold or microcarrier.

- Automation Core: AI-driven control systems monitor and adjust growth parameters to maintain ideal conditions.

- Harvest and Refinement: Proteins are extracted, filtered, and processed into final food forms—burgers, powders, or hybrid products.

- Waste Loop: Byproducts are captured, recycled, or used in other industries, closing the sustainability loop.

This closed-system design minimizes land use, water consumption, and waste—making protein production both localizable and scalable.

Distribution: The New Supply Chain

In traditional agriculture, supply chains span thousands of miles—from farms to processors to distribution centers. Automated bioreactors upend this model.

Because protein production can occur anywhere with access to electricity and clean water, food manufacturing becomes decentralized. Cities, campuses, or even hospitals could host small-scale bioreactor facilities, reducing transport costs and carbon emissions.

This shift aligns with a broader trend in manufacturing—distributed production—where automation enables goods to be made closer to demand, not just where land is cheap.

Economic and Ethical Implications

The economic logic is compelling. Once systems reach maturity, production costs could undercut livestock farming by removing dependencies on feed, fuel, and farmland.

Ethically, it offers a major shift: protein without slaughter, land clearing, or antibiotic use. For educators and parents, it raises a fascinating question—what happens when “farming” no longer requires animals at all?

It’s not just a technological innovation; it’s a redefinition of food ethics and environmental stewardship.

Challenges Ahead

The path forward isn’t frictionless.

- Energy Demand: Maintaining sterile, powered systems at industrial scale is resource-intensive.

- Public Perception: Consumers may hesitate to embrace food from “labs” rather than “fields.”

- Regulation: Governments are still designing frameworks to ensure safety, labeling, and environmental accountability.

Still, momentum is building fast. Pilot plants in Singapore, Israel, and the U.S. are already producing measurable yields of cultivated meat and dairy proteins.

The Classroom Connection

For educators, the bioreactor story is a vivid case study in systems thinking. It connects biology, engineering, and ethics in one ecosystem. Students can explore how automation, coding, and biology intersect to solve global food challenges.

In teaching terms, it’s a bridge between STEM literacy and food literacy—a rare opportunity to show innovation that’s both tangible and transformative.

The Bottom Line

Automated protein bioreactors are not science fiction; they’re a blueprint for a post-field food economy. As technology scales, the concept of farming will expand—beyond soil, beyond livestock, and into the realm of code and circuitry.

The next agricultural revolution won’t be planted. It will be programmed.