Tomorrow’s food factories won’t be run by farmers—they’ll be run by code.

The Rise of Software-Defined Food

Cultured meat—also known as lab-grown meat or cell-based protein—is shifting from a biotech experiment to an engineered manufacturing process. Behind this shift lies a quiet but crucial development: the creation of Operating Systems for Food.

These are not metaphorical “systems.” They’re real digital platforms—complete with data architectures, control dashboards, and AI models—that manage every variable in cell-based protein production. The industry calls them MeatOS.

How a Cultured Meat Factory Works

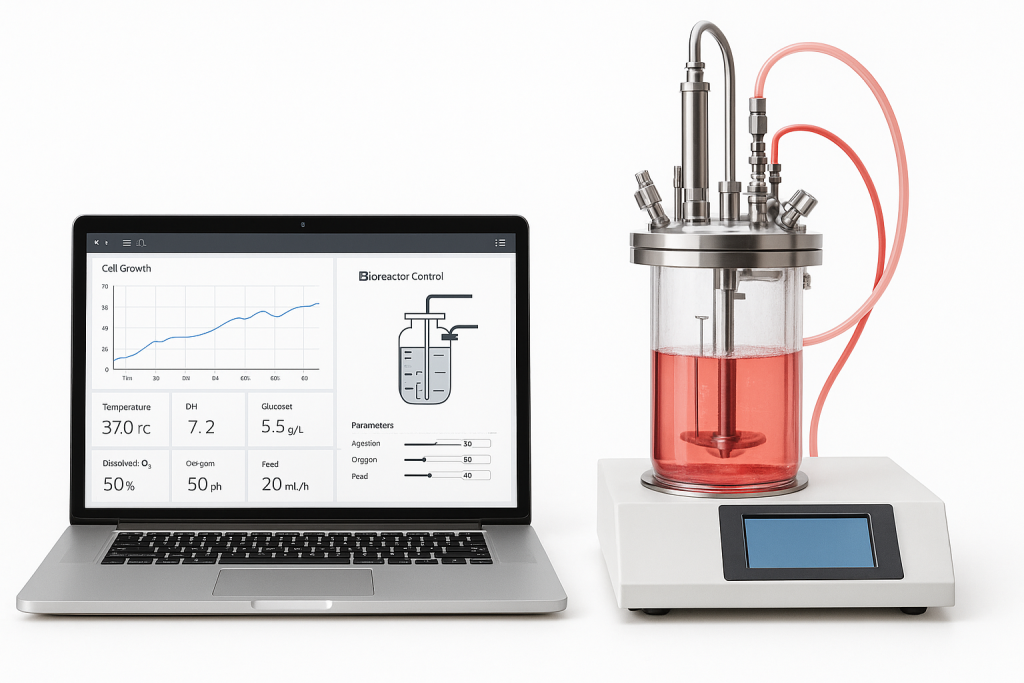

To understand MeatOS, you first need to understand how cultured meat is made. Instead of raising animals, producers grow animal cells in bioreactors—essentially stainless-steel vessels that recreate the environment inside a living organism.

Cells are fed a nutrient-rich medium, provided oxygen, and kept at stable temperatures until they multiply into tissue. What used to be biology is now engineering: a process of controlled cell replication guided by data.

Enter the Operating System

A MeatOS acts as the digital command center for this entire process. It integrates three key functions:

- Bioprocess Control: Monitors temperature, pH, and nutrient flow in real time using sensor networks embedded in each bioreactor.

- Predictive Analytics: Uses AI to forecast growth rates and detect anomalies before they impact yield or quality.

- Automated Optimization: Continuously adjusts conditions based on feedback loops—just like an autopilot system for cellular agriculture.

This combination ensures consistency and scalability, two of the hardest challenges in cultivated meat production.

Why Software Is the New Farmer

Traditional farming depends on human observation and weather patterns. Cultured food depends on data flow and machine learning.

A single cultured meat facility might contain dozens of bioreactors, each generating terabytes of data on cell density, oxygen saturation, and nutrient uptake. MeatOS platforms translate this data into decisions—deciding when to add nutrients, when to harvest, and how to allocate energy for optimal efficiency.

Software doesn’t just manage the process—it learns from it. The more production cycles it runs, the smarter and more efficient it becomes.

Systems Architecture: What’s Under the Hood

A typical cultured food operating system includes multiple layers:

- Hardware Interface Layer: Connects sensors, pumps, and robotic arms for real-time monitoring.

- Data Management Layer: Aggregates raw process data into structured formats for analysis.

- AI and Simulation Layer: Predicts outcomes under different bioreactor configurations and simulates optimal growth conditions.

- User Interface: Provides human operators with control dashboards for visualization, alerts, and process overrides.

This architecture allows for global visibility—engineers can monitor and control production remotely across multiple facilities.

The Analytics Advantage

In cultured meat production, small deviations can have big consequences. Predictive analytics helps mitigate that risk.

Machine learning models can identify subtle chemical shifts that signal contamination or stress in cell cultures long before they’re visible to the human eye. Over time, these insights allow facilities to increase yield, reduce energy use, and standardize quality—an essential step toward making cultured meat affordable at scale.

Ethics and Transparency in Code

When food becomes software, new ethical questions arise:

- Who owns the algorithms that govern food production?

- Should consumers know how digital systems shape what they eat?

- How do we secure data integrity in the food supply chain?

Educators and parents alike have a role to play in shaping food literacy for the digital age—helping the next generation understand that nutrition is no longer just a product of soil and sunlight, but also of code and computation.

The Classroom Connection

For classrooms, MeatOS offers a vivid teaching model for systems thinking. It connects biology, computer science, and ethics in one framework. Students can analyze how feedback loops, automation, and AI all contribute to solving real-world sustainability problems.

Cultured food factories are not just feeding people—they’re teaching us how to manage complex, adaptive systems that could apply to healthcare, energy, or climate science.

The Future of Food Systems

By 2035, many experts predict that major protein companies will operate hybrid supply chains—part farm, part factory, part server cluster. The MeatOS won’t replace farmers—it will extend what “farming” means into the realm of code.

The next frontier of agriculture is not just biological—it’s computational. Food is becoming an information system.