The next industrial revolution won’t be built on scale—it will be grown on connection.

From Global Efficiency to Local Resilience

Globalization was efficient until it wasn’t.

For decades, the world optimized production around a single goal: scale. Massive factories, sprawling supply chains, and just-in-time logistics drove costs down and consumption up.

But that system’s fragility has become clear. Pandemics, geopolitical conflicts, and climate disruptions revealed a hard truth: global efficiency often sacrifices local resilience.

Distributed bio-manufacturing offers an alternative. Instead of centralizing production in mega-facilities, it distributes it across small, adaptable biological hubs—systems that can grow materials, fuels, and medicines locally using renewable inputs.

In short, small isn’t just beautiful anymore. Small is sustainable.

What Is Distributed Bio-Manufacturing?

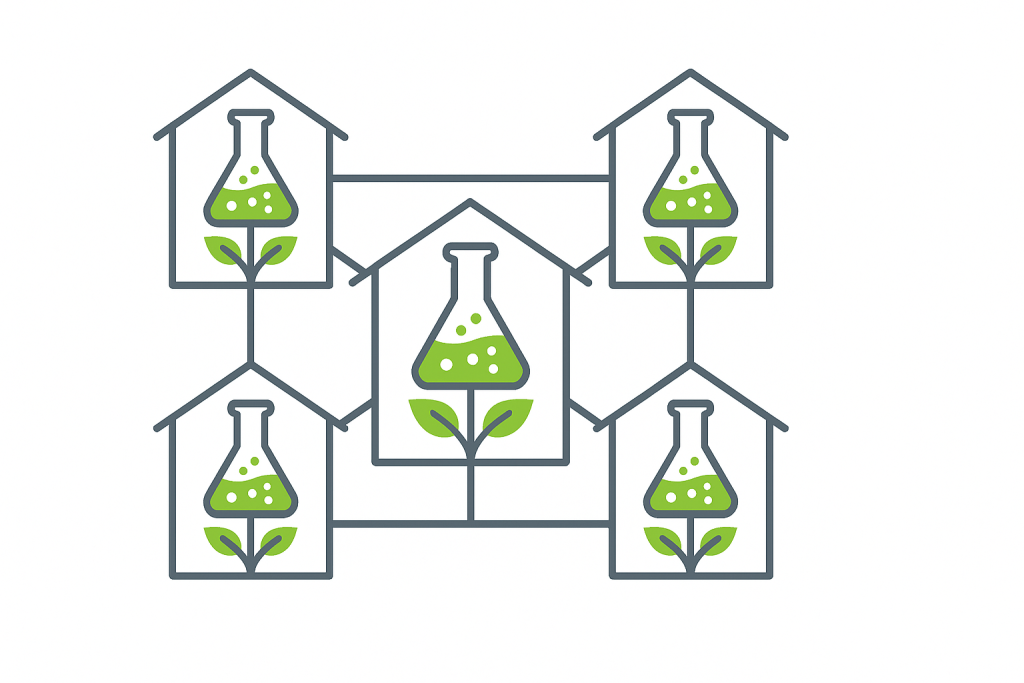

Biology turns production into a living network.

Distributed bio-manufacturing uses programmable organisms—microbes, cells, or enzymes—to produce goods in small, modular facilities located close to where they’re needed.

These “bio-hubs” operate like biological micro-factories, running processes that can:

- Turn agricultural waste into bioplastics.

- Produce medical supplies or food proteins on demand.

- Capture carbon and convert it into usable materials.

Each hub can be scaled up or down depending on community needs. And because the underlying code (the genetic design) is digital, it can be shared instantly across regions, allowing production to be replicated anywhere on Earth—without shipping raw materials halfway around the world.

The Economics of Regeneration

Traditional economics extract. Regenerative economics circulate.

Global supply chains were built to maximize profit through volume. Distributed bio-manufacturing flips that model by optimizing for resource efficiency and ecological health.

Here’s how it changes the equation:

- Reduced transportation costs – Goods are produced locally, cutting fuel and logistics expenses.

- Resource recovery – Waste streams become feedstock for new production cycles.

- Energy efficiency – Biological systems operate at ambient temperatures, using less power than chemical or mechanical processes.

- Local value creation – Communities keep more of the wealth generated by their production.

This approach doesn’t just sustain—it regenerates. It turns economic growth into a function of ecological intelligence, not extraction.

Small Hubs, Big Impact

Decentralization doesn’t mean disorder—it means resilience.

Distributed bio-hubs can operate independently yet coordinate globally, forming a biological network economy. If one region’s production is disrupted, others can take over, much like a natural ecosystem compensates for local stress.

Compare this to the centralized systems of today, where a single bottleneck—say, a shipping port or rare mineral source—can ripple through the global economy.

By decentralizing production, we build an economy that is:

- Adaptive: Able to respond to regional needs and shocks.

- Equitable: Empowering communities to produce rather than depend.

- Sustainable: Rooted in renewable, circular material flows.

The future factory might not be a megastructure—it might be a small lab at the edge of town.

Education and Workforce Transformation

Preparing students to work with life, not just machines.

Distributed bio-manufacturing will demand new skill sets—part biology, part data, part design. Educators and parents can prepare students by emphasizing bio-literacy, systems thinking, and ethical innovation.

Vocational training will evolve too. Instead of assembly lines, young workers may manage bioreactors, monitor microbial processes, and design living materials. These are local jobs with global relevance, merging sustainability with technology in ways traditional industries can’t.

Equity Through Local Production

When production is local, opportunity can be too.

Globalized manufacturing has often widened inequality—profits concentrate where capital is abundant, while resource-rich regions remain dependent.

Distributed bio-manufacturing reverses that trend by localizing ownership and control. Communities that host bio-hubs can:

- Create region-specific supply chains.

- Retain economic value within local economies.

- Customize products to local cultural or ecological needs.

By putting tools of production back in the hands of local innovators, biology becomes a platform for economic inclusion.

The Circular Logic of Biology

In nature, nothing is wasted. In biology-based industry, nothing has to be.

Each bio-hub is part of a circular system—inputs and outputs flow between agriculture, energy, and waste management sectors.

For example:

- Food waste can feed microbes that produce bioplastics.

- Those bioplastics can be composted back into nutrients.

- Nutrients sustain the next cycle of biological production.

This “closed-loop” design mirrors ecosystems, where efficiency comes not from speed or volume but from balance.

A New Definition of Efficiency

Efficiency isn’t about doing more—it’s about needing less.

Distributed bio-manufacturing challenges the old notion that growth must come from expansion. Instead, it proves that density and diversity of production—many small hubs working in harmony—can outperform centralized giants.

In this model, sustainability isn’t a tradeoff. It’s a structural advantage.

Conclusion: Small Is Regenerative

We once built economies that stretched across the globe. The next era will bring them home.

Distributed bio-manufacturing is not about scaling down—it’s about scaling smart. It aligns economics with ecology, replacing fragility with flexibility and inequality with inclusion.

When we stop measuring success by size and start measuring it by resilience, small doesn’t just become viable—it becomes vital.

The future won’t be built in factories.

It will be grown in communities.