The next climate revolution won’t come from offsets—it will come from engineered life.

From Carbon Emitter to Carbon Consumer

Traditional industry is built on extraction.

For two centuries, manufacturing has relied on fossil feedstocks—mined, refined, and burned into the atmosphere. The logic was simple: growth first, emissions later.

But biology operates differently. Living systems don’t extract—they convert, recycle, and adapt. The BioEconomy leverages this natural efficiency, reprogramming microbes to capture and repurpose carbon rather than emit it.

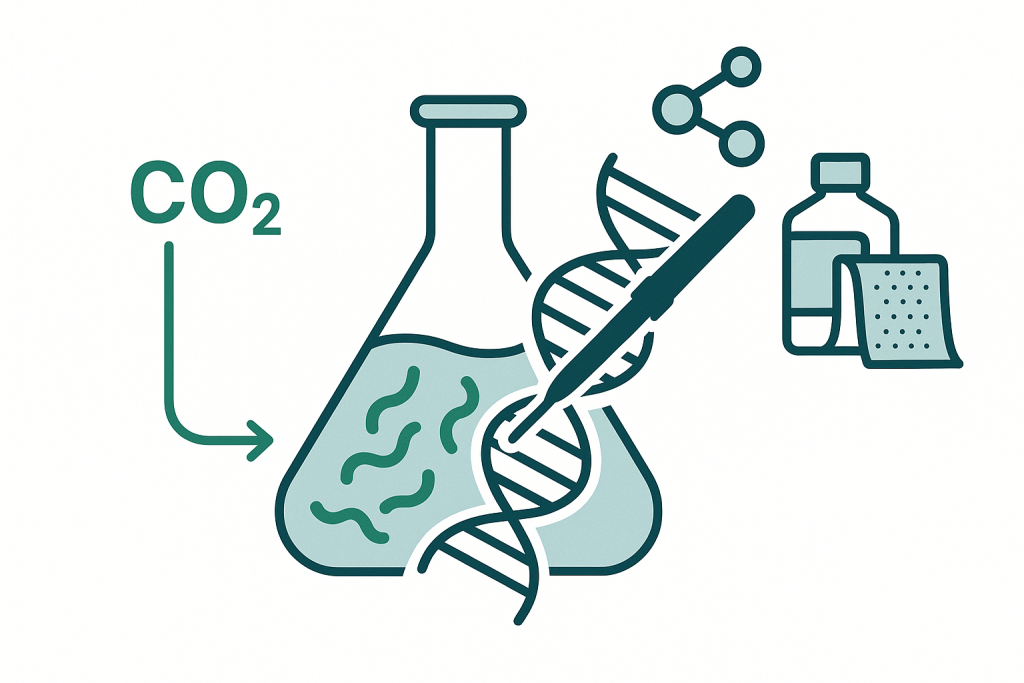

Gene editing, particularly CRISPR, is now turning that biological efficiency into industrial infrastructure.

How Gene Editing Changes the Climate Equation

CRISPR makes microbes programmable factories.

Through targeted DNA edits, scientists can design bacteria, yeast, or algae to metabolize carbon dioxide and transform it into valuable materials—plastics, fuels, textiles, even food proteins.

This shift redefines the industrial process at every level:

- Input: CO₂ becomes the raw material, not the waste.

- Process: Bioreactors replace smokestacks, running at low energy and pressure.

- Output: Products come with a built-in carbon sink, not a carbon debt.

Each edit to a genome represents an edit to the climate balance sheet—where emissions-heavy chemistry is replaced with carbon-negative biology.

From Industrial Emissions to Industrial Inhalation

Imagine an industry that breathes in CO₂ instead of exhaling it.

Companies in the emerging BioEconomy are already developing such processes:

- Carbon-fed polymers grown by engineered microbes that consume CO₂ as feedstock.

- Biofuels and oils produced via algae that capture atmospheric carbon through photosynthesis.

- Fermentation-based cement additives that lock carbon into stable mineral forms.

These systems don’t just reduce emissions—they actively remove carbon from the atmosphere while producing usable goods. That’s the definition of a net-negative industry.

Why This Matters: The Carbon Efficiency Revolution

Decarbonization alone isn’t enough; inversion is.

To meet global climate goals, industries must move beyond neutrality. The future economy will be measured not by how little it emits, but by how much it removes.

Gene-edited biological systems enable:

- Localized carbon capture: On-site microbial production tied directly to emissions sources.

- Energy efficiency: Processes powered by renewable inputs, running at ambient conditions.

- Circular manufacturing: Byproducts recycled as feedstocks in closed biological loops.

The result is a shift from linear extraction to circular carbon flow, where waste becomes raw material for the next production cycle.

Contrast: Biology vs. Legacy Manufacturing

| Legacy Industry | Bio-Based Industry |

|---|---|

| Fossil feedstocks (oil, gas, coal) | Atmospheric CO₂ or waste carbon |

| High heat and pressure | Low-energy biological processes |

| Linear production, high waste | Circular loops, minimal emissions |

| Carbon emitter | Carbon consumer |

This comparison makes clear: biology isn’t just sustainable—it’s transformative.

From Climate Cost to Climate Dividend

Carbon-negative industry is the ultimate economic incentive.

In a future where emissions carry a financial cost, bio-based systems that actively sequester carbon become profitable climate infrastructure. Each molecule of captured CO₂ translates into both reduced environmental impact and tangible product value.

CRISPR-enabled organisms are already demonstrating that the same genome-editing tools that once promised new medicines can now heal the planet’s industrial metabolism.

Conclusion: Engineering the Next Industrial Age

The BioEconomy’s climate dividend is simple yet profound: living factories that turn pollution into production.

Through gene editing, microbes are being trained not just to make, but to unmake—absorbing what industry once expelled. This marks the transition from managing emissions to manufacturing solutions.

The next industrial revolution won’t be powered by combustion—it will be powered by cells.